3D Printing Environmental Impact: Is It Sustainable?

We are reader-supported. When you buy through links on our site, we may earn affiliate commission.

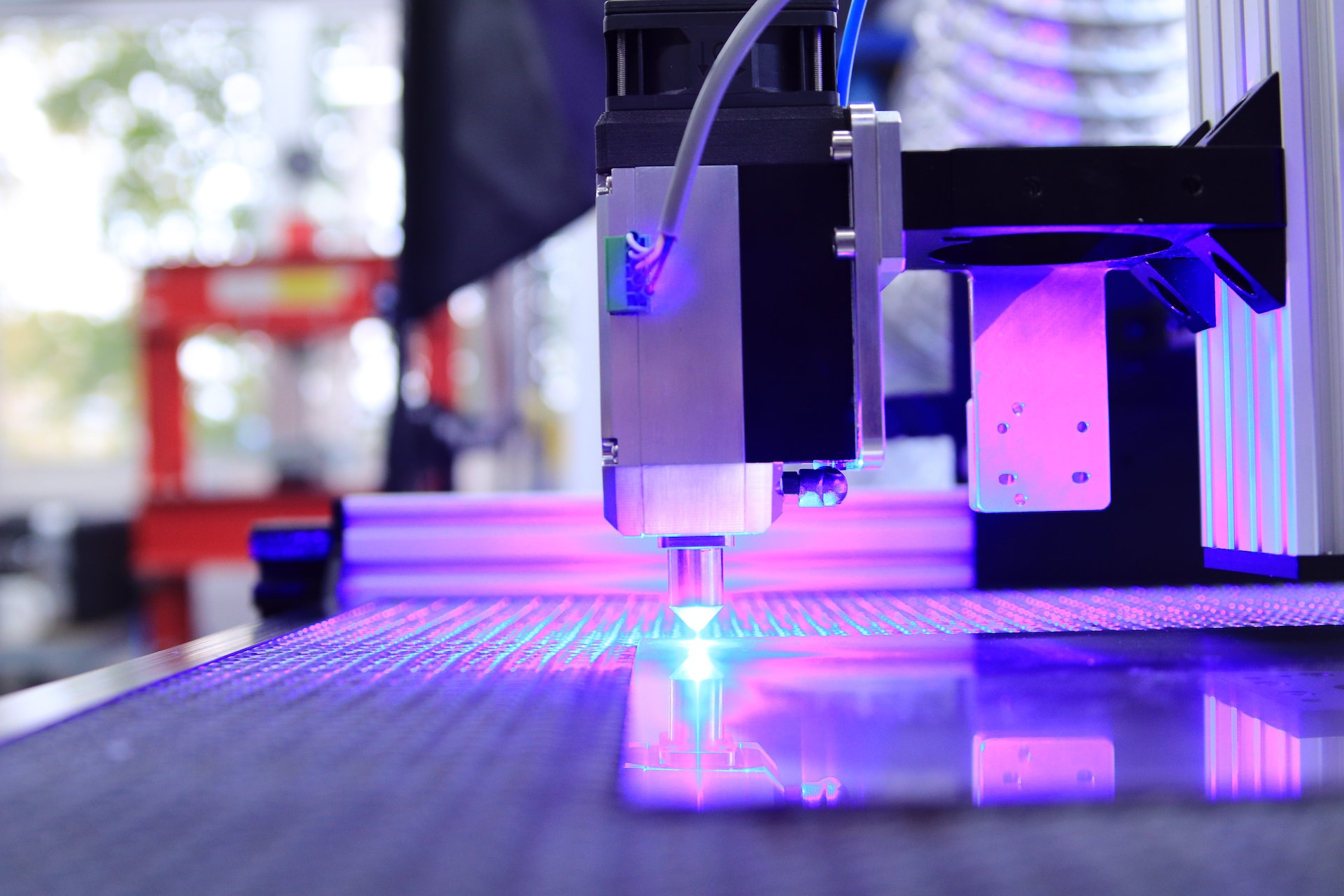

3D printing seems to be the next big thing in terms of technology. People have asked if they can use it to make cars, decor, toys — nearly everything under the sun. Plenty are even using it to create affordable and quick-build houses, decreasing the wait time for new homebuyers and those without housing. However, while this new method shows much potential, environmentalists may wonder about the 3D printing environmental impact. Does the good outweigh the bad enough to warrant making the switch?

How 3D Printing Increases the Sustainability of Other Industries

While 3D printing may seem like it’s only for decor purposes, it has plenty of uses in everyday life. One study examining the eco-sustainability of 3D printing found it had a 70% drop in impact compared to traditional processes. As one can imagine, when it doesn’t take a village to complete a project — it just needs a printer — factories use a lot less energy, lessening their carbon footprint.

In April of 2023, the Additive Manufacturer Green Trade Association (AMGTA) released its first commissioned research on an aerospace low-pressure turbine bracket. One interesting finding was the results of whether 3D printing or standard manufacturing was more energy efficient were inconclusive. The most important factor was if the facility used renewable power. However, the AMGTA notes this outcome was still favorable, as previous studies found additive manufacturing used more electricity than conventional methods.

3D printing also allowed for a 50% weight reduction for the aircraft’s bracket. Over the life of the craft, it reduced carbon emissions by 13,376 kg for every 1 kg of weight minimization. This is an incredible showing of 3D printing’s environmental impact on outside sectors. Imagine being able to decrease the greenhouse gases everyday vehicles like cars and buses release with the help of 3D printing. The results could significantly improve the state of the environment.

Investigations into printing with metal show a similar outcome. Wire arc additive manufacturing can reduce material waste by 40%–70% — a significant result. Less waste means more components can go toward creating more pieces. This helps manufacturers use as much of their materials as possible, decreasing unnecessary spending, transportation and processing. Not to mention, their environmental impact reduction was in the range of twelve to forty-seven percent.

How Housing Can Benefit From 3D Printing

One of the most critical industries in which 3D printing makes a sustainable difference is construction. Places like Dubai hope to use additive manufacturing for 27% of their buildings by 2030, as experts predict the market for this method will grow to $280 million by 2027. Doing so would enable various benefits.

Some of the most significant of these changes are in reducing material costs and wait times. Construction companies won’t have to rely on estimates while ordering components, as their 3D printers will make exactly as much product as they require. This not only helps cost savings but avoids the need to ship in more materials than necessary, improving the carbon footprint of the average home. Additionally, builders can construct homes and commercial buildings much faster than traditional methods, decreasing the need for workers to drive in for weeks.

However, there are some issues with the current method of using 3D-printed concrete as a sustainable alternative. Concrete is one of the most common building materials, but it makes up 4%–8% of the world’s total carbon footprint. Replacing it with sustainable materials is necessary, but the 3D-printed version has less strength than the original material. However, recent developments in how the printer lays the concrete have made strides in durability. Adding 1%–2% steel fibers is also making a significant difference.

3D printing is not yet the standard way to build homes. However, more improvement will emerge the longer innovators work on developing new methods. These discoveries utilizing the structure of a lobster’s shell are just the beginning of what is to come. Eventually, there will be new filaments that are even more environmentally friendly, more components that are clean and energy-efficient printers for lower emissions than ever before.

3D Printing Environmental Impact

While all that sounds fantastic, there are concerns to contend with before every industry flips to 3D printing. One of the most durable filaments for these printers — acrylonitrile butadiene styrene (ABS) — is petroleum based, releases harmful fumes and is not recyclable. There is a form of filament that is much more eco-friendly and derives from corn, but ABS has a much longer life span. Thus, manufacturers will find they have to choose between sustainable production and components until scientists discover new methods.

Another problem comes in developing a final product. While there are sites where people can access previously created designs, a manufacturer developing a method of printing their items will have to go through testing. This aspect can create more waste than many realize, making 3D printing’s environmental impact more notable in the early stages. Also, machine errors may always be a part of the process. The more challenging the design, the more chances a printer can falter in following orders.

Other issues arise in the printing process. The printer will need to be on as it creates whatever someone decides to make. If that power comes from an unclean source, it will use fossil fuels and release unintended emissions. A manufacturer considering switching to 3D printing would need to switch to renewable energy to avoid subverting their sustainability efforts.

As time goes on and innovations become more efficient, 3D printers will likely use less energy. However, the energy use of one is about the same as subtractive manufacturing — or traditional methods — according to one study. 3D printing’s environmental impact will be more than many would hope until then.

The Pros and Cons of 3D Printing Environmental Impact

Additive manufacturing certainly has plenty of potential. Research shows it reduces waste, has less degradation and is much faster to build with. However, it does have some current drawbacks that should iron out with time. 3D printing’s environmental impact will drop as new inventions arise.

Share on

Like what you read? Join other Environment.co readers!

Get the latest updates on our planet by subscribing to the Environment.co newsletter!

About the author

Maria Visser

Maria serves as the Assistant Editor of Environment.co. A true foodie and activist at heart, she loves covering topics ranging from veganism to off grid living.